Great for lacing shoes or skates!

The hockey stick bench is a great piece of fully functional furniture that doesn’t require a lot of sticks. Composite sticks are really strong so even if you space them out, they make a good seat. Unlike many hockey stick benches which bolt to wooden or plastic frames, this design will give plans for using sticks for the legs and pucks for the feet, adding an extra “cool” factor. Though the hockey stick bench legs are at an angle here, the design can be easily modified for the legs to be perpendicular to the seat and therefore, simpler to build.

Need a head start on the project? Purchase the puck feet here! Set of 4 puck feet.

Design Approach

The breakdown of the hockey stick bench plans is as follows:

- Seat

- Legs and Leg Supports

- Puck Feet

Tools and hardware for the project:

Tools

- Miter Saw

- Router or Mill

- Drill

- Allen wrenches

- Wrench set

- Bubble level

- 4 bar clamps (2 greater than 3 ft)

- Several 2″ spring clamps

- Glue

Hardware

- 14 sticks

- 8 : 5/16″-18 Shoulder Bolt, 2.75″ long

- 8 : 5/16″ Washer

- 8 : 5/16″ Nuts

- 4 : #10-32 Shoulder Bolt, 2.5″ long

- 4 : #10 Washer

- 4 : #10-32 Nuts

- 8 : #6 1.5″ Sheet metal screw

- 27: #6 1.25″ Sheet metal screw

- 4 : 3″ Mending plates (if reinforcement desired)

- 16: #8 1/2″ socket cap screws (if reinforcement desired)

Build

Seat

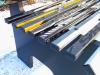

The first order of business is the seat. You’ll want to use only those sticks that are greater than 41.5″ in length. Don’t try to glue or attach broken sticks together to try to get the length right. It’s for a bench, so you don’t want to sit down and have the seat break!

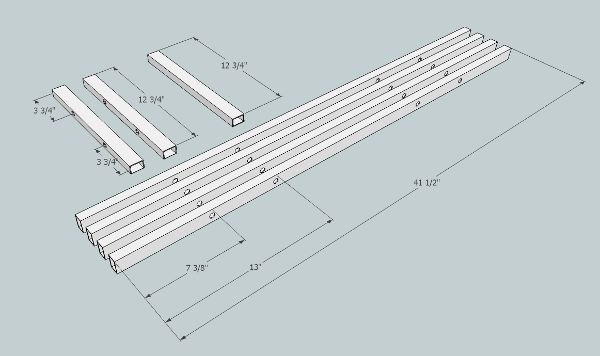

First, cut nine sticks to 41.5″ length. Then, cut three seat attachment pieces to 12.75″ in length and in two of them, drill holes of about 7/32″ in diameter 3.75″ inches from either end. Drill the hole clean through the stick. Choose four of the nine seat slat sticks and drill 3/8″ holes in the locations shown in the image below. (Note: image does not show other seven sticks.)

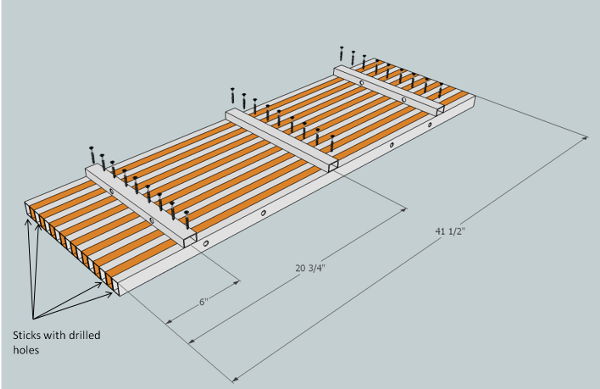

Using spare sticks or other material as spacers (I highly recommend using spare sticks), clamp all nine of the 41.5″ sticks together where two of the sticks with the holes should be on both outer edges. The spare sticks help hold everything together and the keep the spaces uniform for a good look. Secure the seat attachment pieces on the bottom of each stick as shown in the images below using #6, 1.25″ sheet metal screws ensuring the two bench attachment pieces with holes are on the outside. For the #6 screws, I recommend drilling a pilot hole with a 7/64″ bit to make driving the screws much easier. The spare sticks are highlighted orange in the image below.

Go ahead and remove the spare sticks in between….

and you’ve got a bench seat!

Legs and Leg Supports

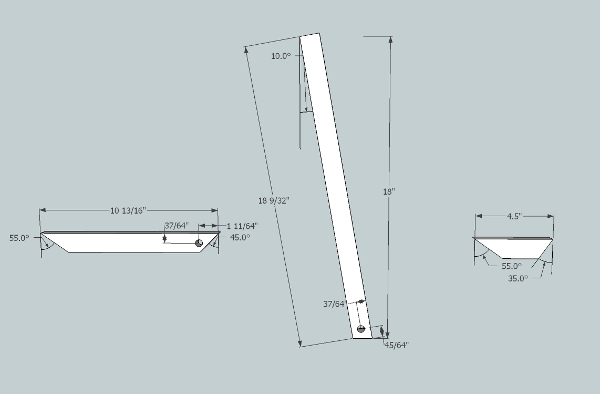

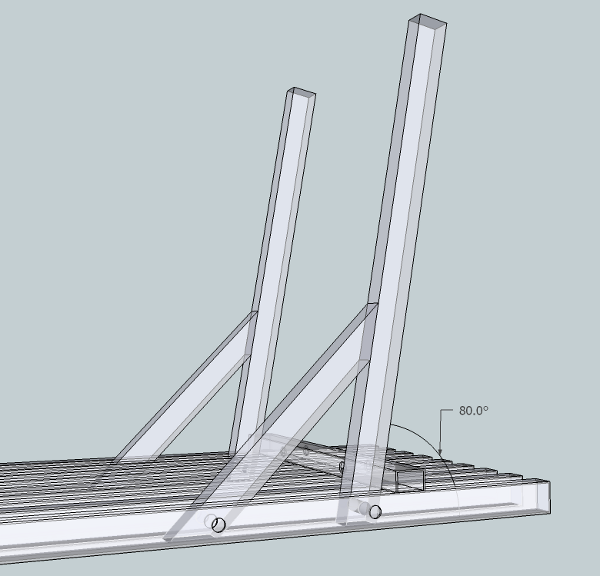

Next we’ll add the legs and the leg support pieces. The three pieces for a single leg are shown in the image below: an approx 18″ leg, a 10 13/16″ support piece and a small 4.5″ support piece. You’ll have to make four of all three pieces. NOTE: If you’re not going to use puck feet, you’ll want to make sure that both ends of the legs are cut to be parallel to each other so the bench sits flat, i.e. both ends need a 10 degree miter cut.)

You might find it tricky to cut the 55 degree angles using a miter saw since their range can be limited to 45 or 50 degrees. One option (WARNING: This is potentially very dangerous!) is to set the miter to 35 degrees, and put the stick perpendicular to the guide rail to make the cut. A second, much safer option, is to build a guide/jig to hold the piece while doing a more shallow miter cut. There are plenty of pictures/guides online for doing this.

Take the main leg and the longer support pieces and insert them between the first two bench slats as shown below. The leg face with the 10 degree angle cut should face face down on the bench so the leg angles outward. The support piece should have the 45 degree cut face down between the bench slats, putting the 55 degree cut against the leg.

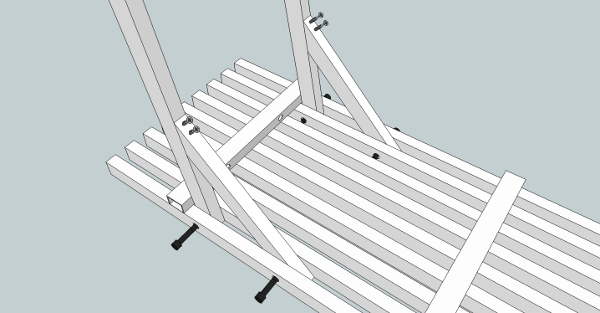

Using two 5/16″-18 2.75″ shoulder bolts, bolt the legs and the supports pieces to the bench. Be sure to use a washer behind the bolt head and nut. Next, drill a #6 1.5″ sheet metal screw and a #6 1.25″ sheet metal screw from the support piece into the chair leg. The 1.5″ screw should be on the inside since it has further to travel. The drawing below summarizes the connections that should be made for each leg at this step. Repeat this process for all four legs.

Next, we will attach the small support pieces. You might have noticed now that we didn’t pre-drill the hole for attaching this small support piece to the bench attachment piece. We waited until this step because of the high variance in the exact location of the seat support piece holes when you made the seat. We’ll line everything up now to make an accurate measurement for marking the hole location.

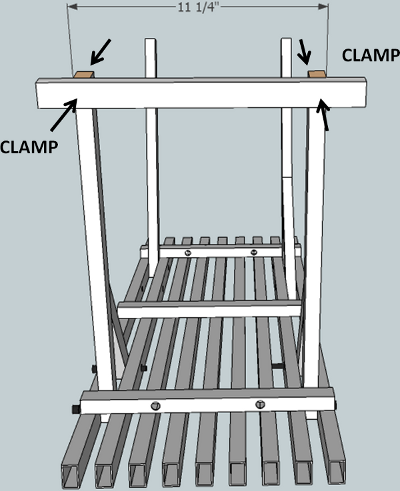

First, measure the distance between legs on a short side of the bench down a the seat starting at the outer edge of each leg. It should be approximately 11.25″ (it depends on the exact size of the bench slat spacing you used). Clamp a temporary brace between the same two legs near where the feet will go; this brace should be clamped so the distance between the feet of these two legs is the same distance you just measured between them at the seat. Doing so makes sure your legs will vertical when we add this final support pieces and not tilted inward or outward. See the image below.

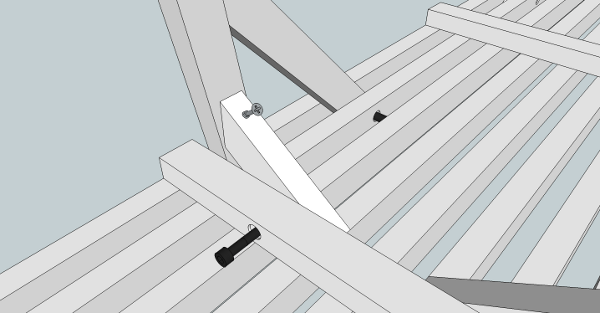

Now that the legs are vertical, slide the small support pieces into their anticipated locations, with the 55 degree face down on the bench slats and the 35 degree face on the legs. (We don’t use two 45 degree angles because the two pieces would be nearly touching each other and the connection bolt to the seat attachment pieces would be very close to one of the sheet metal screws that hold the slats on.) Using a 7/32″ drill bit, slide it through the seat attachment piece holes and twist it, marking the small support piece beyond with a small divot. Marking the drill point this way eliminates any wander from making a circle with an inserted a pencil. Since you used a 7/32″ drill bit to make the hole, it should fit right in and be nicely centered. Do this for all four legs.

Remove the small support pieces and using each divot as a guide, drill through them with the 7/32″ bit. Returning the small support pieces to the bench, you can run #10-32 bolts through both pieces and seat attachment pieces as shown below. Again, make sure you put washers on both the head and the nut of the bolt (not shown here).

Holding each support piece in place, drill in a #6 1.25″ sheet metal screw.

You should have legs that look similar to the bench below.

It’s time to reinforce the leg joints. You should notice small gaps between the leg support pieces and the legs. In the picture above, it’s right above the ‘S’ on the leg. Fill in these and all other gaps using a very high strength adhesive such as epoxy. You can buy lots of different types of epoxies from generic hardware stores. A general purpose epoxy will do if it’s an indoor bench. The biggest difference will be the cure time but very generally speaking, the longer the cure time, the stronger the bond.

(Optional Step:) You can choose to add additional reinforcement to the leg/leg-support-piece junction by incorporating a mending plate. These are metal plates with holes in them designed for just this purpose and are available at local hardware stores. I’ve made benches with and without the plates; both are strong and secure, but some are interested in that little bit extra insurance! When using mending plates, if they come with screws, they’re usually flat head and I would advise against using them. Instead use 1/2″ length #6 or #8 torx or socket cap screws which will hold much better.

Puck Feet

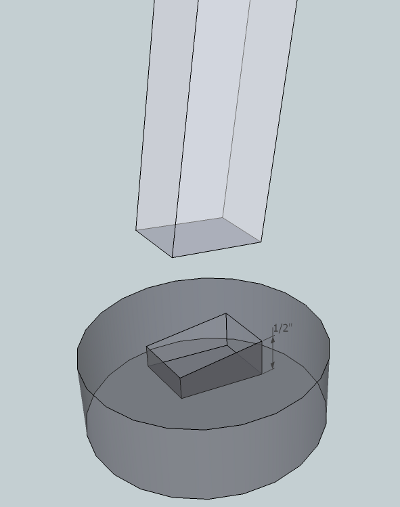

Puck feet add a great final touch to the bench so I recommend adding them; however, they are not for the faint of heart and you’ll need a router or end mill to do it. Even if you’re not perfect, some glue can cover your tracks! Remove the puck material about 1/2″ down on the inside part of the puck since that will be where the longer portion of the stick inserts. Measure each leg’s cross section dimensions (1-3/16″ x 0.75″ or so, depending) and undersize the hole in the puck by about 1/32″ (this depends on the puck hardness). This will allow the stick to compression fit into the puck. Given that every stick has a slightly different size and that different brand pucks have different durometers, I don’t show those dimensions in the drawings and you’ll need to adjust to your situation with some trial and error. If your hole is accidentally too large, you can epoxy the stick into the puck.

Once you’ve routed or milled out all four puck feet, push them on and you have your bench!

Model

For a full model of the bench, visit Models.